Magnetization Directions

Magnetization Directions (Polarity Options) – Complete Guide

What is Magnetization Direction?

Magnetization direction (also called polarity orientation) describes how the magnetic field is aligned within a magnet. When a magnet is manufactured, the internal magnetic domains are permanently aligned in a specific direction under a strong external magnetic field. This alignment determines where the north (N) and south (S) poles are located, as well as how the magnet interacts with other magnets and materials.

Understanding magnetization direction is crucial because two magnets of the same size and grade can behave very differently depending on their polarity orientation. Engineers and designers must carefully select the correct magnetization to achieve the desired performance in motors, sensors, speakers, medical devices, and countless other applications.

Why is Magnetization Direction Important?

-

Application Performance – Motors, generators, and actuators often require precise magnetic pole arrangements.

-

Assembly Considerations – Correct polarity ensures magnets can be mounted, bonded, or integrated without repelling forces.

-

Magnetic Field Distribution – Different magnetization directions create different external field shapes, suitable for sensing, focusing, or shielding.

-

Efficiency – Optimized pole orientation can significantly increase torque, sensitivity, or holding force.

How Magnetization Directions Are Created?

The way a magnet’s poles are arranged is not arbitrary — it is determined by the manufacturing process and the intrinsic material properties. Different magnet families (NdFeB, SmCo, Ferrite, AlNiCo, bonded types) achieve their magnetisation direction in different ways:

Sintered Neodymium (NdFeB) Magnets – Anisotropic

-

In sintered NdFeB, the easy axis of magnetisation is fixed during the pressing and sintering stage.

-

Fine alloy powders are compacted inside a strong magnetic field, forcing the grains to align in a preferred orientation (axial, transverse, or radial, depending on the tooling and field).

-

Sintering then “locks in” this orientation, producing an anisotropic material.

-

After machining and coating, the magnet is charged in a pulsed magnetiser, but the direction is already predetermined — the charging step only saturates the magnet along its built-in orientation.

-

Attempting to magnetise in another direction yields very poor performance.

Samarium Cobalt (SmCo) Magnets – Anisotropic

-

SmCo magnets are also anisotropic and rely on powder pressing in an applied magnetic field to establish orientation.

-

Because of SmCo’s high coercivity and thermal stability, the chosen orientation (axial, radial, etc.) is locked during sintering.

-

Multi-pole configurations can later be applied if the geometry (especially rings and arcs) is designed for it.

Ferrite Magnets (Ceramic)

-

Hard ferrites can be produced as isotropic (no preferred orientation) or anisotropic (aligned).

-

In isotropic ferrites, no magnetic field is applied during pressing, so the final magnet can be magnetised in any direction, but with lower energy product.

-

In anisotropic ferrites, the pressing step is carried out under a magnetic field, which aligns grains and produces higher performance — but the direction is fixed.

AlNiCo Magnets

-

AlNiCo magnets are often cast or sintered.

-

Their orientation is controlled by applying a magnetic field during heat treatment (cooling through the Curie point), which aligns the magnetic domains along a chosen axis.

-

Because AlNiCo has relatively low coercivity, its magnetisation can be altered or even demagnetised if handled improperly — so orientation control during manufacture is critical.

Bonded Magnets (NdFeB, Ferrite, or SmCo powders in a polymer matrix)

-

Bonded magnets can be isotropic or anisotropic, depending on whether an aligning magnetic field is applied during moulding.

-

Isotropic bonded magnets can be magnetised in virtually any direction (axial, diametrical, radial, multi-pole), making them very versatile for complex designs like encoders.

-

Anisotropic bonded magnets offer higher performance but with a fixed magnetisation axis.

Multi-Pole Magnetisation

-

Multi-pole patterns (common in ring magnets and encoder applications) are achieved using special magnetising fixtures after the magnet has been manufactured.

-

These fixtures create alternating north–south poles around the circumference or across the surface.

-

For anisotropic materials, the multi-pole magnetisation must still follow the built-in grain orientation (e.g., a radially oriented ring can support circumferential multipoles).

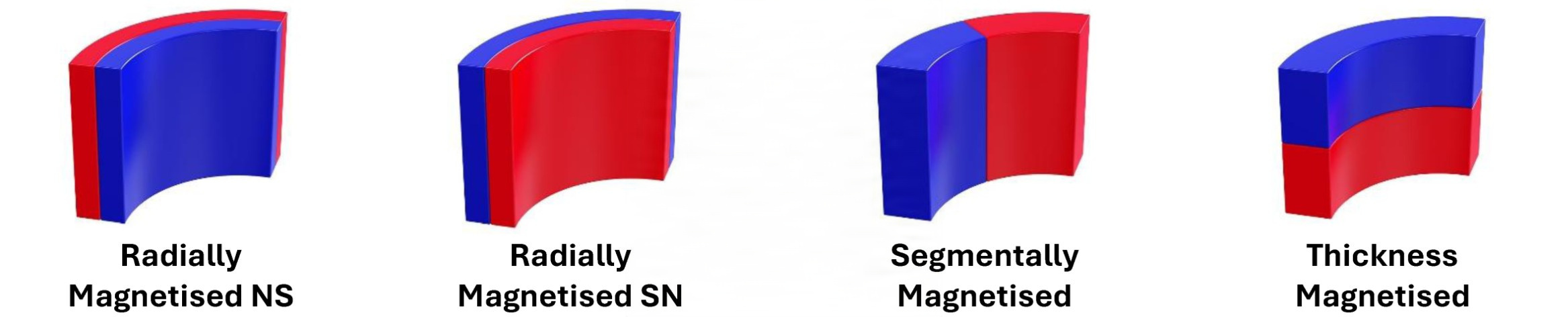

Arc Magnet Magnetization Directions

Arc magnets are commonly used in motors, alternators, and magnetic couplings. Their curved shape allows for precise control of rotating magnetic fields.

-

Arc Magnet Radially Magnetised NS – North pole on the inner radius, South pole on the outer radius.

-

Arc Magnet Radially Magnetised SN – South pole on the inner radius, North pole on the outer radius.

-

Arc Magnet Segmentally Magnetised – Multiple pole segments across the arc, creating alternating fields.

-

Arc Magnet Thickness Magnetised – Polarity passes through the thickness of the arc.

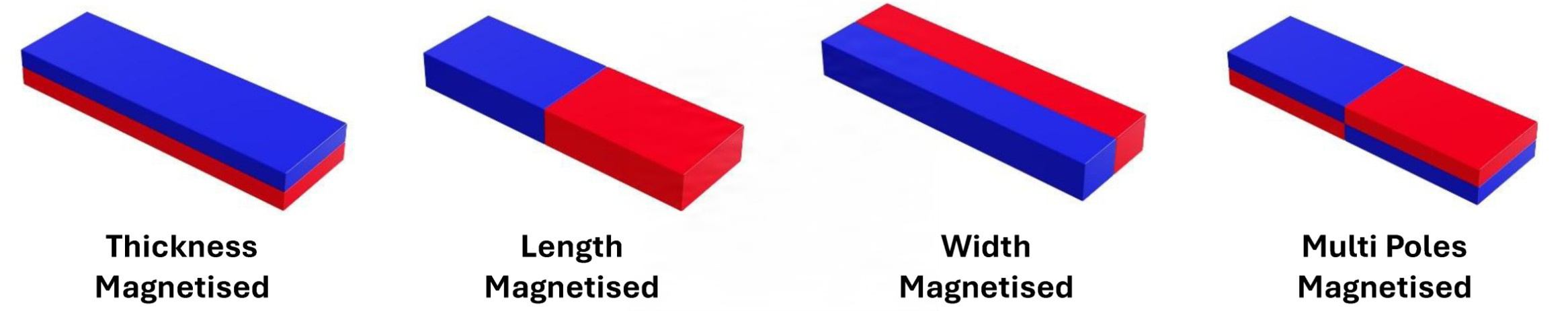

Block Magnet Magnetization Directions

Block magnets (rectangular magnets) are the most versatile form and can be magnetized along different axes.

-

Block Magnet Multi-Poles Magnetised – Several poles aligned across the surface.

-

Block Magnet Thickness Magnetised – Polarity goes through the thickness.

-

Block Magnet Length Magnetised – Polarity passes along the length.

-

Block Magnet Width Magnetised – Polarity aligned through the width.

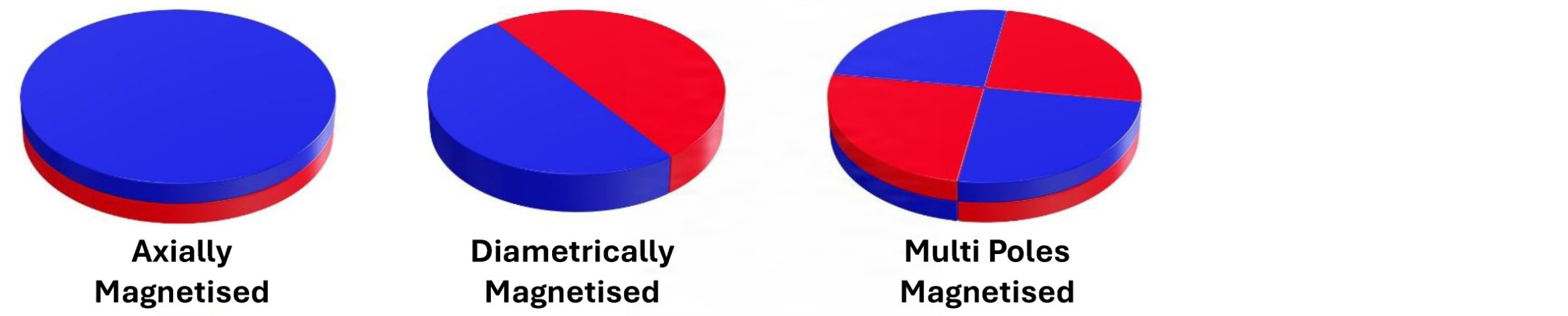

Disc Magnet Magnetization Directions

Disc magnets are commonly used in sensors, electronics, and holding systems.

-

Disc Magnet Axially Magnetised – North on one flat face, South on the opposite face.

-

Disc Magnet Diametrically Magnetised – North and South poles appear on opposite curved sides.

-

Disc Magnet Multi-Poles Magnetised – Multiple poles distributed across the flat circular surface.

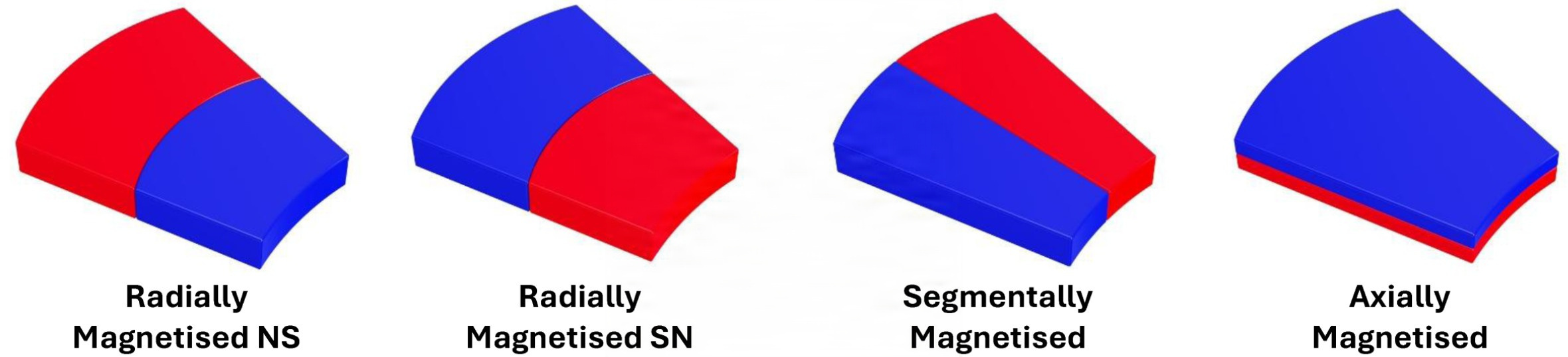

Wedge Magnet Magnetization Directions

Wedge magnets are widely used in motors, generators, sensors, and specialized magnetic assemblies. Their tapered wedge shape allows efficient use in circular magnetic arrays and ensures uniform field distribution in compact designs.

-

Wedge Magnet Radially Magnetised NS – North pole on the inner radius, South pole on the outer radius.

-

Wedge Magnet Radially Magnetised SN – South pole on the inner radius, North pole on the outer radius.

-

Wedge Magnet Segmentally Magnetised – Multiple pole segments across the wedge, creating alternating fields.

-

Wedge Magnet Axially Magnetised – Polarity passes through the thickness of the wedge.

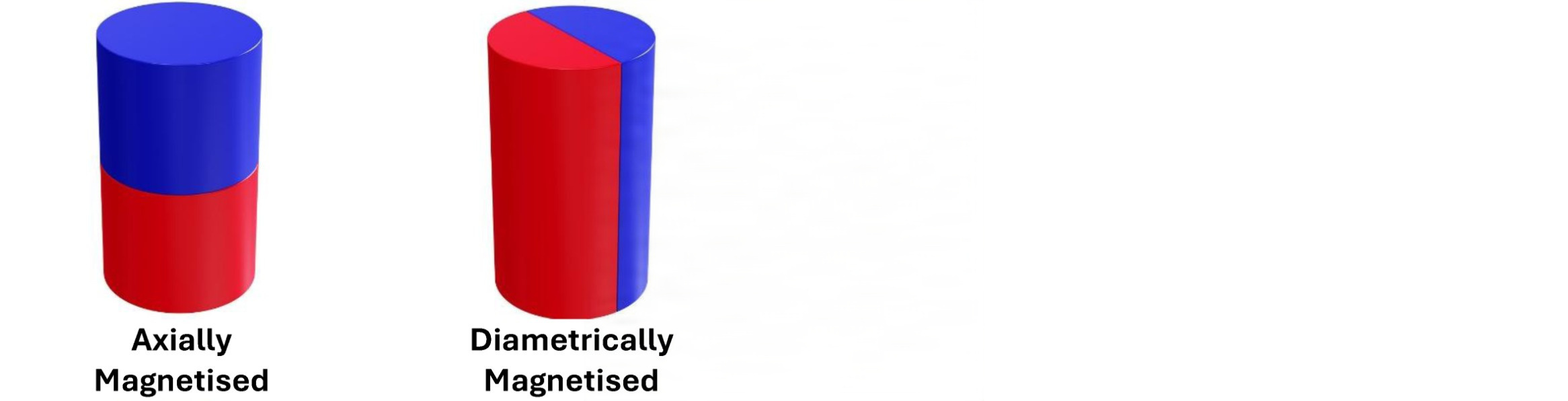

Cylinder Magnet Magnetization Directions

Cylindrical magnets are similar to discs but longer, used in actuators and medical devices.

-

Cylinder Magnet Axially Magnetised – North and South poles on the flat ends.

-

Cylinder Magnet Diametrically Magnetised – Polarity runs across the diameter of the cylinder.

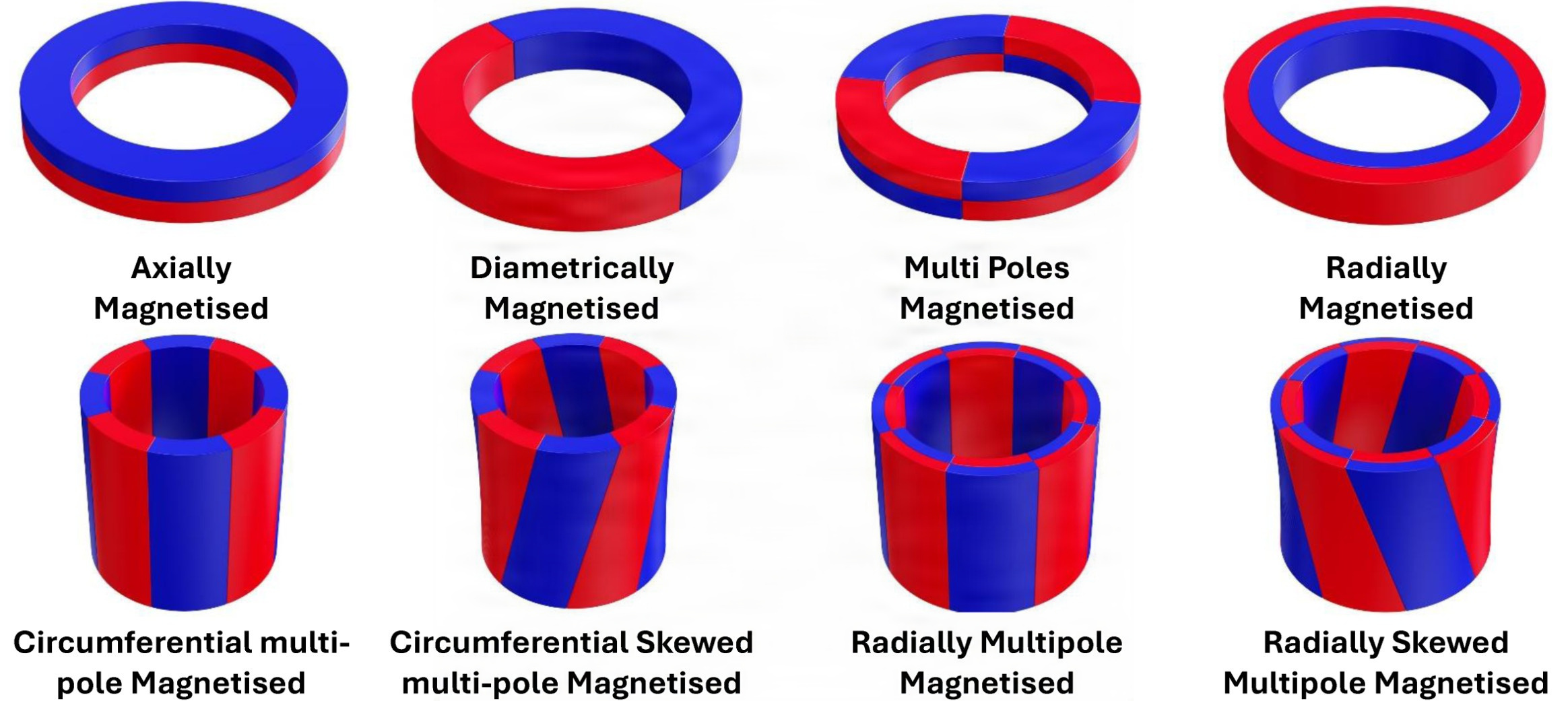

Ring Magnet Magnetization Directions

Ring magnets allow for complex magnetic field patterns, making them ideal for precision encoders, motors, and sensors.

-

Ring Magnet Axially Magnetised – Poles on the flat circular faces.

-

Ring Magnet Circumferential Multi-Pole Magnetisation – Alternating poles arranged around the circumference.

-

Ring Magnet Circumferential Skewed Multi-Pole Magnetisation – Poles arranged in a skewed pattern for smoother field distribution.

-

Ring Magnet Diametrically Magnetised – Polarity across the diameter.

-

Ring Magnet Multi-Poles Magnetised – Multiple poles across the ring surface.

-

Ring Magnet Radially Magnetised – Polarity directed through the radius.

-

Ring Magnet Radially Multipole Magnetised – Multiple radial poles alternating between inner and outer edges.

-

Ring Magnet Radially Skewed Multipole Magnetised – Radial poles arranged at angles for advanced motor applications.

Sphere Magnet Magnetization Directions

Sphere magnets are unique, with uniform geometry for symmetrical field distributions.

-

Sphere Magnet Axially Magnetised – Single axis polarity, creating a natural dipole field.

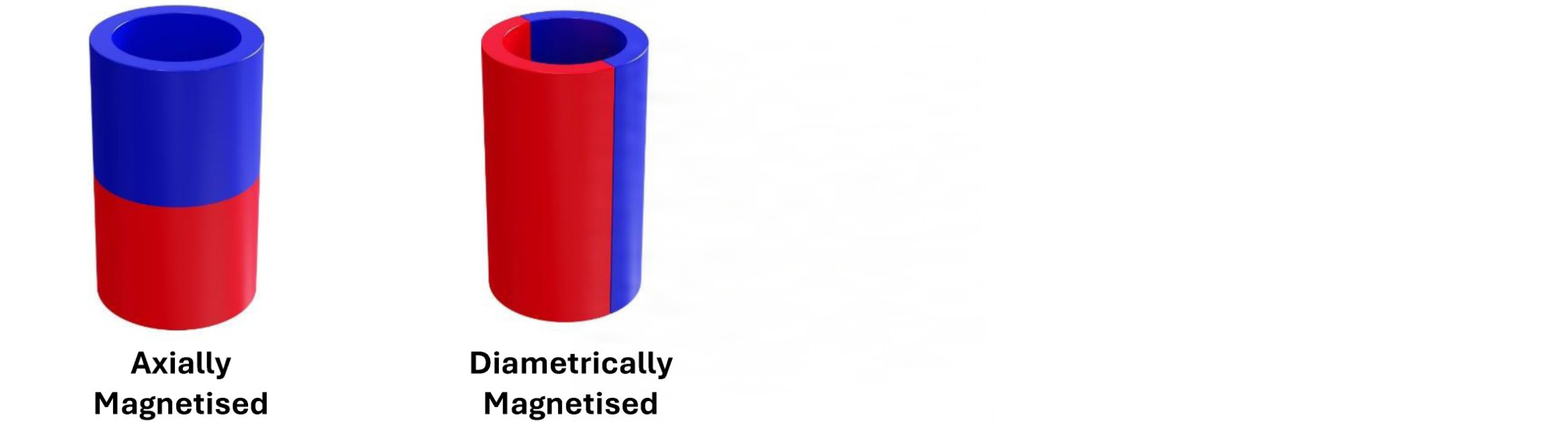

Tube Magnet Magnetization Directions

Tube magnets are essentially hollow cylinders, used in filters, sensors, and rotating machinery.

-

Tube Magnet Axially Magnetised – Polarity across the flat ends of the tube.

-

Tube Magnet Diametrically Magnetised – Polarity across the curved wall of the tube.

Magnetization direction (polarity orientation) is one of the most important design considerations in magnet applications. Choosing the right polarity ensures that your magnet performs correctly in its application, whether in motors, generators, encoders, or magnetic assemblies.

At Magnetop, we provide custom magnets with precise magnetization directions according to your technical requirements. Our team supports you from design through manufacturing to ensure optimal performance and compliance with international standards.

If you have questions or would like to request a custom quotation, please contact us at sales@magnetop.com.au